by Josh Briggs

What Is an Alternator?

An automotive charging system is made up of three major components: the battery, the voltage regulator and an alternator. The alternator works with the battery to generate power for the electrical components of a vehicle, like the interior and exterior lights, and the instrument panel. An alternator gets its name from the term alternating current (AC).

Alternators are typically found near the front of the engine and are driven by the crankshaft, which converts the pistons' up-and-down movement into circular movement. Some early model vehicles used a separate drive belt from the crankshaft pulley to the alternator pulley, but most cars today have a serpentine belt, or one belt that drives all components that rely on crankshaft power. Most alternators are mounted using brackets that bolt to a specific point on the engine. One of the brackets is usually a fixed point, while the other is adjustable to tighten the drive belt.

You can spot the alternator (with the tag hanging off it) in the foreground of this shot of a stock car engine. You can also see the serpentine belt looped around it.

Alternators produce AC power through electromagnetism formed through the stator and rotor relationship that we'll touch on later in the article. The electricity is channeled into the battery, providing voltage to run the various electrical systems. Before we learn more about the mechanics of the alternator and how it generates electricity, let's look at the various parts of an alternator in the next section.

Alternator Components

For the most part, alternators are relatively small and lightweight. Roughly the size of a coconut, the alternators found in most passenger cars and light trucks are constructed using an aluminum outer housing, as the lightweight metal does not magnetize. This is important since aluminum dissipates the tremendous heat generated by producing the electrical power and since the rotor assembly produces a magnetic field.

If you closely inspect an alternator, you'll find it has vents on both the front and back side. Again, this aids in heat dissipation. A drive pulley is attached to the rotor shaft on the front of the alternator. When the engine is running, the crankshaft turns the drive belt, which in turn spins the pulley on the rotor shaft. In essence, the alternator transfers the mechanical energy from the engine into electrical power for the car's accessories.

On the back side of the alternator you'll find several terminals (or connecting points in an electrical circuit). Let's take a look at those:

S terminal - Senses battery voltage

IG terminal - Ignition switch that turns the voltage regulator on

L terminal - Closes the circuit to the warning lamp

B terminal - Main alternator output terminal (connected to the battery)

F terminal - Full-field bypass for regulator

Cooling is essential to an alternator's efficiency. It's easy to spot an older unit by the external fan blades found on the rotor shaft behind the pulley. Modern alternators have cooling fans inside the aluminum housing. These fans operate the same way, using mechanical power from the spinning rotor shaft.

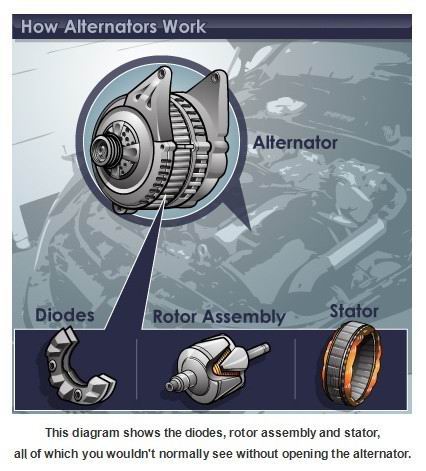

As we start to disassemble the alternator, we find the diode rectifier (or rectifier bridge), the voltage regulator, slip rings and brushes. The regulator distributes the power the alternator creates, and it controls the output of power to the battery. The rectifier bridge converts the power, as we'll learn in the next section, while the brushes and slip rings help conduct current to the rotor field winding, or wire field. Now let's crack the coconut open.

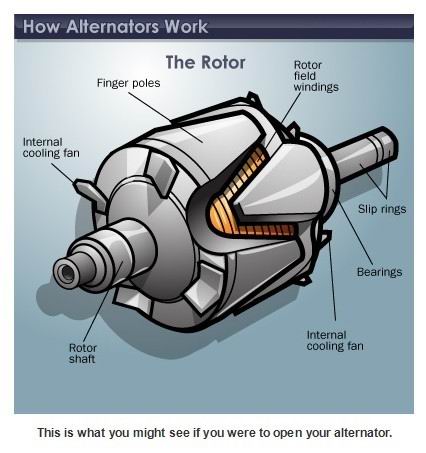

Opening the alternator reveals a large cylinder with triangular finger poles around the circumference. This is the rotor. A basic alternator is made up of a series of alternating finger pole pieces placed around coil wires called field windings that wrap around an iron core on the rotor shaft. Since we know the pulley attaches to the shaft, we can now visualize how the rotor spins inside the stator. The rotor assembly fits inside the stator with enough room or tolerance between the two, so the rotor can spin at high speeds without striking the stator wall. On each end of the shaft sits a brush and a slip ring.

As we touched on briefly, alternators generate power through magnetism. The triangular finger poles fixed around the circumference of the rotor are staggered, so the north and south poles alternate as they surround the wire rotor field windings. This alternating pattern creates the magnetic field that in turn induces voltage into the stator. Think of the stator as the catcher's glove as it harnesses all the power created by the spinning rotor.

All these components work together to give us the power we need to run our vehicles. Tesla captured this electrical energy and used it to light up cities, but we only need enough volts to power our stereo, lights, windows and locks. Let's take a look at how the alternator produces that power in the next section.

Understanding Alternator Power Output

In the early days, cars used generators rather than alternators to power the vehicle's electrical system and charge the battery. That's not the case anymore. As automotive technology evolved, so did the need for more power. Generators produce direct current, which travels in one direction, as opposed to the alternating current for the electricity in our houses, which periodically reverses directions. As Tesla proved in 1887, alternating current became more attractive as it generates higher voltage more efficiently, something necessary in contemporary automobiles. But car batteries can't use AC power since they produce DC power. As a result, the alternator's power output is fed through diodes, which convert the AC power to DC power.

The heavy-hitting rock band AC/DC formed in Australia in 1973. Legend has it the founding members got their name after reading the term off the back of an appliance. The band played up to its name, with lead guitarist Angus Young and lead singers Bon Scott and then Brian Johnson giving the band its distinctive high-voltage sound. The group saw major success in the 1980s and is still going strong, more than 30 years after its formation.

The rotor and the stator are the two components that generate power. As the engine rotates the alternator pulley, the rotor spins past three stationary stator windings, or wire coils, surrounding a fixed iron core that makes up the stator. This is referred to as a three-phase current. The coil windings are evenly spaced at intervals of 120 degrees around the iron shaft. The alternating magnetic field from the rotor produces a subsequent alternating current in the stator. This AC current is fed through stator leads into a connecting set of diodes. Two diodes connect to each stator lead to regulate the current. The diodes are used to essentially block and direct the current. Since batteries need DC current, the diodes become a one-way valve that will only allow current to pass in the same direction.

Three-phase alternators have three sets of windings; they're more efficient than a single-phase alternator, which produce a single-phase AC current. When working properly, the three windings produce three currents that make up the three phases. Adding all three together produces the total AC output of the stator.

The two basic stator winding designs are delta wound and wye style. Delta wound are easily identifiable by their shape, as they're triangular. These windings allow for a high current flow at lower RPM. Wye windings resemble the flux capacitor seen in "Back to the Future." These windings are ideal for diesel engines, as they produce higher voltage than delta stators at even lower RPM.

After the AC/DC conversion, the resulting voltage is ready to use in the battery. Too much or too little voltage can damage the battery, as well as other electrical components. To ensure the correct amount, a voltage regulator determines when and how much voltage is needed in the battery. One of two types of regulators are found in most alternators: The grounded regulator works by controlling the amount of negative or battery ground going into the winding in the rotor, while a grounded field type works the other way around - by controlling the amount of battery positive. Neither poses an advantage over the other.

With so many components working to create the electricity vital for our vehicles, it's safe to say the alternator is a crucial component under the hood. But like many parts on our cars, they fail. The next section will give you an idea of how to determine if you are about to be stranded and what you can do if you need to replace your alternator.

The Life and Death of an Alternator

As we saw in the beginning of the article, a failing alternator will kill a battery and ruin your day. But why did the alternator fail in the first place? Alternators have moving parts, get dirty and are subject to stress from heat and cold. As a result, the internal parts gradually wear out.

One of the most common failures is bearing failure. The needle bearings that allow the rotor to spin freely inside the stator can break down from dirt and heat. When the bearings fail, the rotor will not spin efficiently and can eventually seize. Usually an alternator with bearings failure makes a loud grinding noise. If you suspect this problem, it's only a matter of time before the alternator gives up. Older vehicles with generators tend to require much more maintenance than newer models, but there's no hard and fast rule for how long an alternator will last. It varies from manufacturer to manufacturer.

You can take several easy steps to diagnose whether your alternator is on the fritz. First, most cars today have a dashboard light that glows when the ignition is switched on. This light usually is represented with a symbol of a battery. Have you ever heard a buzzing noise when the key is on, but the car isn't running? That's the voltage from the battery running through the charging system. If this bulb is burned out, chances are the alternator won't work. The car may start, but as we learned, it's just a matter of time before the battery drains and the electrical system fails.

As a rule, a three-phase alternator can operate with only one of the stator windings operational, although it's only one-third as efficient. To test whether your car had an issue with one of its stator windings, you'd need to use a voltmeter to check the voltage. (You can buy a basic voltmeter at an electronics store.) This is called a load test. Since the battery produces DC power, set the voltmeter to DC rather than AC. Connect the red lead (or wire) to the positive terminal and the black to the negative. With no accessories on, start the car and raise the RPM to around 1,000. The voltage should register around 14 volts. Anything less than 12 may indicate a problem. Next, turn on the headlights, air conditioner, radio and anything else that draws electrical power. Rev the engine and check the voltmeter. Again, the voltage should register around 14 volts. If you have a failing alternator, the voltage will be well below 14 volts. If so, it's time to replace the alternator.

Before you decide you need to yank the alternator and replace it, make sure you check the serpentine belt. If the belt is worn or loose, the alternator won't function properly. A bad belt is easy to replace and won't set you back much, usually less than $20. But if you have to replace the alternator, you have options. Read on to learn how to go about replacing an alternator and what it may cost in the next section.

Alternator Replacement

For the most part, alternators are less expensive than say, a power steering pump or air conditioner compressor. Nevertheless, you have alternatives to forking out a lot of cash for a replacement alternator. Many automotive stores sell remanufactured or rebuilt alternators at a discounted price. For instance, a Beck/Arnley alternator for a 2002 Honda Accord with a 3-liter V6 engine can cost $229 new, versus $163 for the same part, only remanufactured.

While alternators are relatively inexpensive in comparison to some of the other components on your engine, some can be expensive depending on the car make. If you owned a 2005 Porsche 911 Carrera GT for instance and wanted to replace the original Bosch alternator, you could expect to pay well over $300, and that's for a remanufactured component.

Sometimes alternators are easily accessible and simple to replace for the amateur mechanic. With a modest amount of automotive experience and the proper tools, replacing an alternator in your garage can be done. But more and more cars don't have room under the hood, and the alternators can be difficult to reach without first removing several other components. In this case, it's best to take your car to an experienced technician who can do the job quickly.

If you happen to own an alternator that has a repair kit available for sale, you can really save some money. Alternator repair kits run between $12 and $30, depending on which components you need to fix. Again, you need the proper tools and a little know-how, but if you're able to find the right kit and know what you're doing, you can rebuild an alternator for a fraction of the cost of even a remanufactured unit.

One thing is certain: A bad alternator will ruin a good battery if you don't address it quickly. Batteries can only be recharged so many times before they'll lose their ability to hold a charge. For the most part, if the battery isn't relatively old, it should survive. But an older battery that is constantly drained and charged, drained and charged will have a shorter life span than a battery operated under normal conditions. The average life span of a battery is usually around 48 months.

High-output alternators have become popular with custom car shops and in high-performance cars. They produce higher voltage at idle and make more power for vehicles that draw an excessive amount of electricity. For example, custom cars with lavish audio and video systems draw more electricity than the stock alternators can handle. As a result, companies such as HO Alternators make alternators for several makes and models. Some custom shops are even installing dual-alternator systems to handle the additional electrical loads seen in custom vehicles.

For more information on vehicle electrical systems, please check out the lots more information in RIBO Parts Articles.